Cable Crossover Machine

A few years ago I realized how useful cable crossover machines were while doing physical therapy after a shoulder injury. Cable machines can be more more flexible than freeweights for isolating small muscle groups and functional training. This flexibility is gained because resistance can be applied from almost any angle rather than positioning the body relative to a force normal to the ground.

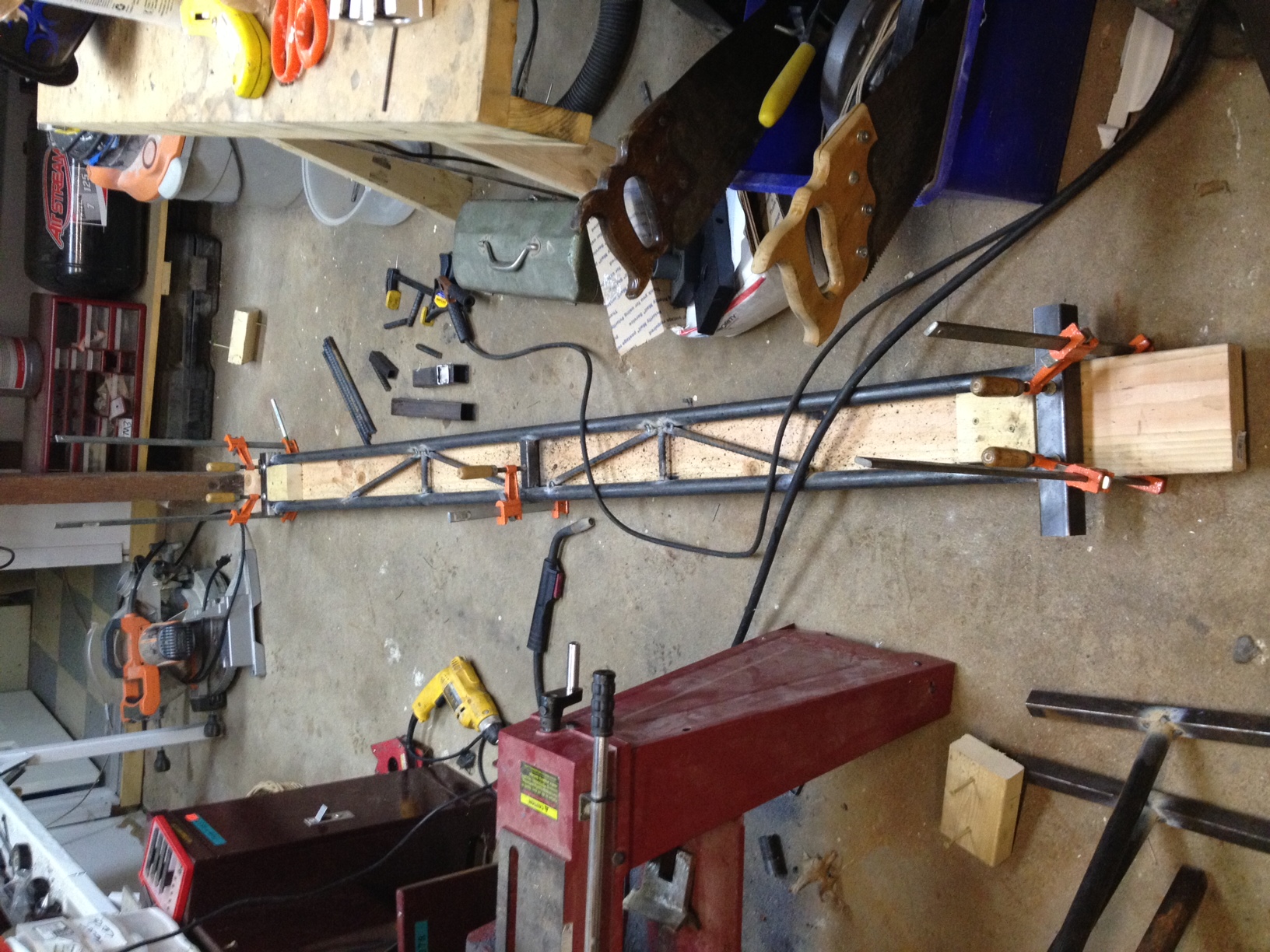

Here is one side support being welded. The support is made of 1.5" square pipe on the top and bottom, 3/4" steel pipe for the sides, and 1/2" rebar for the cross pieces. The wood jig was a 2x6 with some 2x4 blocks to hold everything in place. The blocks were removed as more cross pieces were welded in starting from the center of the support. After the first two opposing pieces of rebar were welded in the support was much stiffer and I was a little less worried about the structure pulling itself into a parallelogram-ish type shape. I made one of these supports for each side of the machine.

|

The brownish crud around the welds is slag leftover from welding; I currently use flux core wire.

The top and bottom of the machine were made from 1.5" angle iron and 1.5" flat bar. These hold the vertical side supports parallel and will support the guide rods for the weight stack. Pictured is the top piece. Later on I will weld on some brackets for pulleys and guide rods. The bottom piece is made in the same way however it is wider to prevent the machine from toppling (additional outriggers will be added to keep it from toppling during actual use).

|

Here is the frame assembly mocked up. The bottom is bolted together and the top has some clamps to check the fit before I drill the bolt holes in the side supports. Some pipe will be welded across the back of the frame to reduce sideways deflection.

|

The weight stack has plenty of clearance on either side. I'll weld in some angle iron to support the guide rods and then turn some clamps to hold the rods in place on the support. The guide rods are 1" diameter hardened and ground steel.

|

I'll be updating this as more work gets done. I only have a chance to work on this a day or so per month so progress is very slow.