Extracting Large Broken Screws

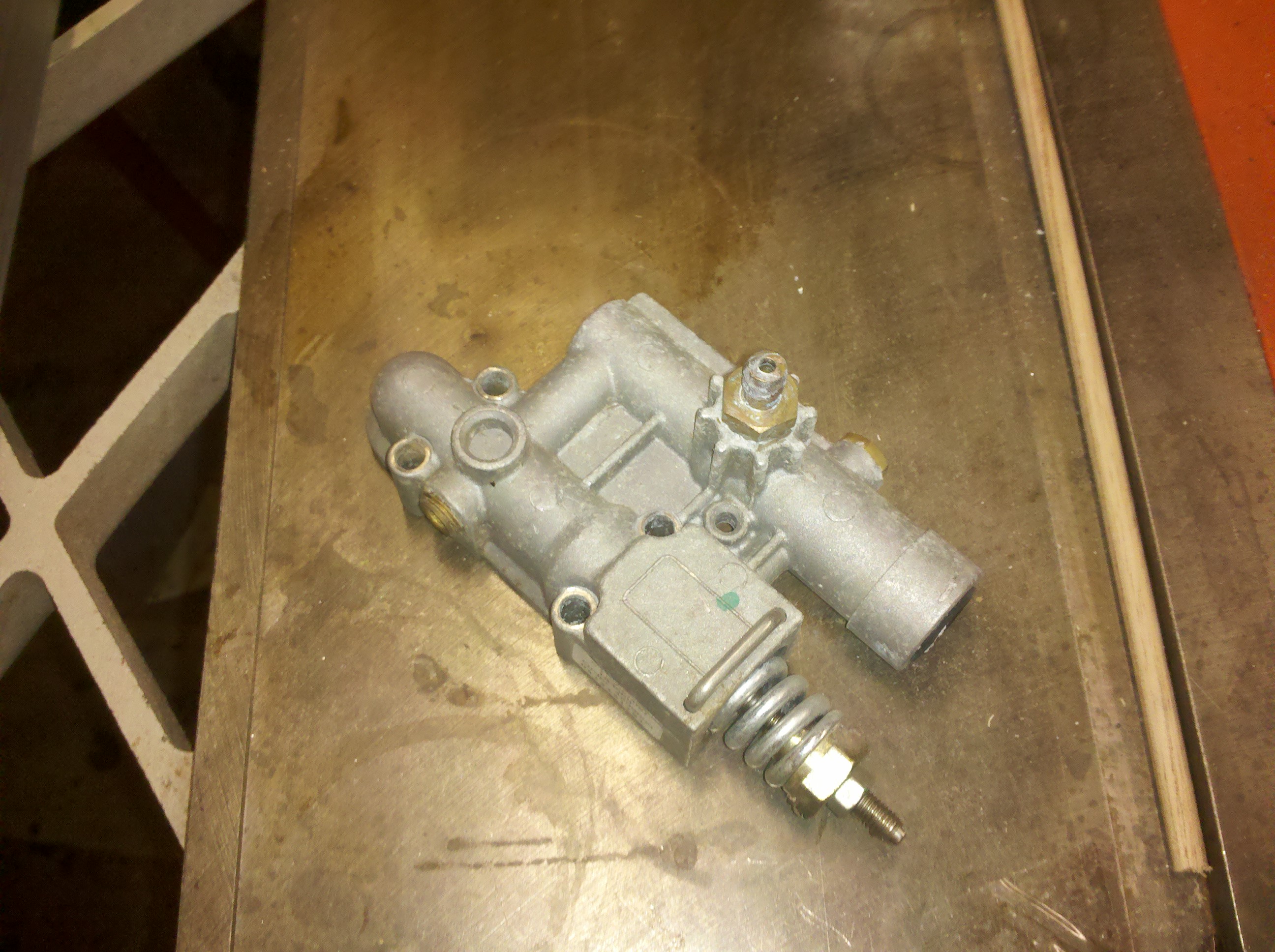

An adapter broke off in the pump manifold on my pressure washer, a new manifold was $60 and a new adapter is $15- an entire new pump assembly is $120. I don't like getting screwed out of money so I decided to attempt to remove the broken stub from the adapter so I could reuse the manifold and just replace the $15 adapter.

|

|

|

In order to remove the adapter I needed to be able to unscrew it. To accomplish this I milled a slot across the top of the stub so I could use a screwdriver(in the past I have used handheld rotary tools for this purpose too). First I jammed up the inside of the stub with a paper towel so chips don't fall into the internals of the manifold. There were two parallel flat faces on the manifold body so the entire thing was mounted in a vice.

|

|

|

The slot was milled using a 1/8" endmill and is 3/8 long center to center. I didn't have any screwdrivers wide enough to fit across the whole slot so I made a key out of some scrap metal.

|

|

|

The point of this post is to say by actually getting my hands dirty I saved $60 in an hour. It is always worth learning how things work and how to fix them, though its cool if you don't want to - parts suppliers need someone to rip off.